Uncertainty of Measurement and Sieve Calibration

No measurement is 100% accurate. Measure the same object ten times in a row, and there’s a chance that the measurements won’t be identical. Measure that same object ten times in row every day for a week, and it’s almost certain that the measurements will vary by a small amount. Temperature changes, equipment stability, human error, etc. all contribute to cause a small amount of variability in measurements. When attempting to measure things precisely it’s important to be aware of this tendency for measurements to vary. Uncertainty of Measurement is what we use to quantify the degree to which measurements are likely to vary.

All labs that are compliant with ISO 17025 are required to adequately consider and account for the uncertainty in their measurements. They must examine all the relevant sources of uncertainty in their measurements and report a combined uncertainty when they produce results. This ensures that anyone who relies on these results in the future can easily account for the uncertainty inherent in the results. The combined uncertainty is often multiplied by a ‘coverage factor’ to create an Expanded Uncertainty. This helps ensure that the probability that the reported uncertainty adequately covers extreme cases is high.

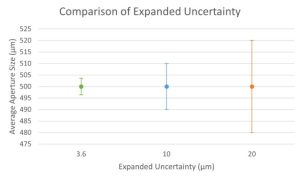

In practical terms, it can be useful to think of uncertainty of measurement as a buffer around measurements. The uncertainty extends around the measured value and you can be confident that the ‘true’ value lies somewhere inside the buffer. At Glenammer our expanded uncertainty of measurement is, in most cases, ± 3.6 µm. Let’s say we were calibrating a sieve with 500 µm mesh, and we found that the average aperture size in this sieve was 500 µm. When we factor in our expanded uncertainty of measurement, we can see that the ‘true’ average aperture size is likely to be between 496.4 µm and 503.6 µm. As the uncertainty of measurement increases, the range of possible ‘true’ values increases. The following graph shows that even when the measurement results are equal, differences in measurement uncertainty change the appropriate level of confidence in the results. The higher the uncertainty, the lower the precision of the measurements.

Please fill out our contact form below to stay in touch. By using this form you are opting in to our newsletters.