Established in 1998 by Allen Matthews, the company was founded on the innovative principle of producing better quality laboratory sieves made exclusively from stainless steel. At that time most sieves were made from brass – a weaker and less environmentally friendly material than stainless steel – and Allen was keen to find a superior product and a better manufacturing process in order to help laboratories.

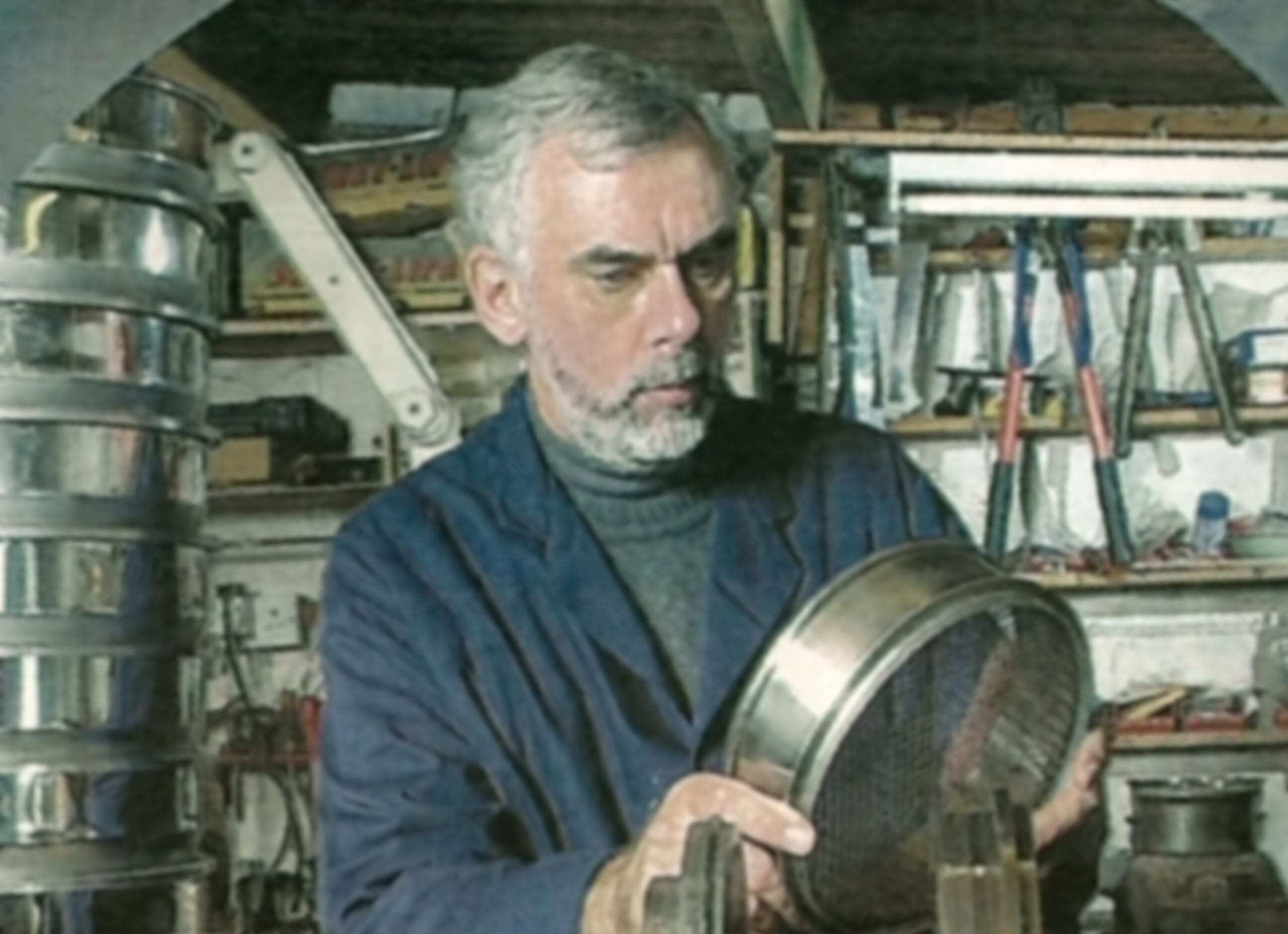

Allen started the business from a small workshop in his garage at his home in Ayrshire, Scotland. The name ‘Glenammer’ originates from the name of a local blacksmith in Allen’s home village. From hammering horseshoes to fit the hooves of the local herd in earlier days, the name struck a cord with Allen and the engineering process used to make test sieves.

The company grew rapidly and in 2005 Glenammer moved to it’s first factory where it was able to further invest in innovative machinery to improve the quality and production process of it’s sieves. Fast forward another 9 years and the company moved into even larger premises in order to provide space for further development and storage of stock.

In 2016 Allan retired, and his daughter, Claire Wallis, now manages the business. From a small, local Scottish business to an international player, Claire is ambitious to continue to grow the business and is enthusiastic about the next stages of development. The company bases it’s management model on the Six Sigma technique to improve it’s business processes and Claire and her team are continually looking at ways to develop the product range and thus many of the sieve production processes are now controlled in house to improve efficiency and enhance product consistency. Glenammer now provides products to a range of industries and laboratories worldwide, from agriculture to civil engineering to food and drink manufacturing, where particle analysis is key and product quality for testing is vital to the success of their business.

Allen started the business from a small workshop in his garage at his home in Ayrshire, Scotland. The name ‘Glenammer’ originates from the name of a local blacksmith in Allen’s home village. From hammering horseshoes to fit the hooves of the local herd in earlier days, the name struck a cord with Allen and the engineering process used to make test sieves.

From a small, local Scottish business to an international player manufacturing world-class test sieves and exporting to 70 countries worldwide, we are excited about the next stages of development.

Please fill out our contact form below to stay in touch. By using this form you are opting in to our newsletters.